Automated vial labeling systems and their maintenance are crucial to pharmaceutical production because they lead to innovation and effectiveness of the labeling process. To increase the life of the equipment, reduce time off, and ensure that the equipment follows the set industry standards, maintenance is important. The following are some tips that will help the users in the proper maintenance of the high speed vial labeling machines.

Internal Cleaning and Inspection

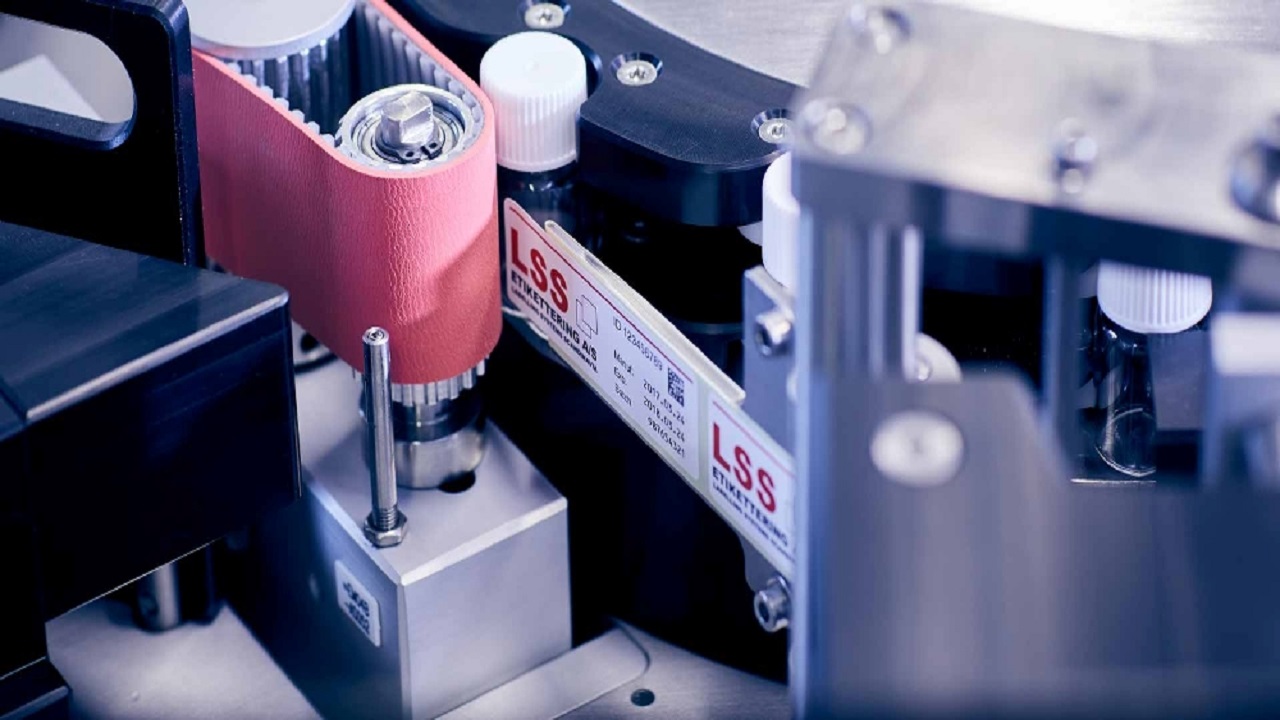

The labeling machine is likely to have dust, adhesive residue, and product particles on different parts of the labeling machine after some time. To avoid this, implement a routine cleaning schedule:

Daily Cleaning

Clean the outer surface of the machine and make sure you scrub off the deposit on rollers, belts, and label applicators.

Weekly Inspection

Look for signs of wear on the label sensors as well as rollers and belts. Worn parts should be replaced immediately to avoid any breakdown of the machine.

Adhesive Buildup Removal

The adhesive must be cleaned using solutions that are permitted for use within industries in removing adhesives on the machines without affecting the parts.

Lubrication of Moving Parts

Lubrication always minimizes friction and reduces early wear of handling or operational parts. Follow these tips:

- Ensure you use the manufacturer’s recommended lubricants in the machinery.

- Grease gears, chains, and bearings amongst other elements after a given duration of operation.

- Do not over-grease because this will attract dirt and cause mechanical problems.

Calibration and Alignment

To maintain labeling accuracy, periodically check and calibrate the machine’s settings:

Sensor Alignment

Make sure that sensors are well placed to correctly read vials and labels.

Label Placement

Ensure that labels are affixed at the right place on the vial. This is because misalignment can cause production errors.

Speed Settings

Accomplish a change in the speed of the constructed machine about the actual production speed without necessarily decreasing the precision level.

Regular Software Updates

Contemporary vial labeling machines have software-driven parts. Keeping the software up to date ensures optimal performance:

- Update the firmware of the product to the most current versions offered by the manufacturer.

- To prevent data loss during updates back up system configurations and data regularly.

- Educate train operators familiar with new additions to software to enhance its use.

Preventive Maintenance Scheduling

Preventive maintenance minimizes the risk of unexpected breakdowns:

- It is recommended that the maintenance program should be by the manufacturer-recommended program.

- All wiring and all sensors that are connected to the electrical part of the engine should be checked for damage or signs of excessive usage.

- Backup systems and emergency stop functions should be tested often to keep yourself in compliance with safety requirements.

Training of Operators and Implementing Best Practices

Proper training for machine operators can enhance maintenance efforts:

- Teach train operators to identify the first symptoms of wear or failure.

- Promote a commitment to smooth performance as per the set working policies and safety procedures.

Ensure that, sometime later, general operating skills training is given to the operators to update them more often on advanced techniques to adopt.

Conclusion

These maintenance practices will be of great importance in the running of the vial labeling machines with few interferences. Cleaning, calibration, preventative maintenance, and operator training not only prolong the life expectancy of your assets but also increase output and numbers relevant to regulatory requirements. Regular maintenance also ensures that your labeling is done effectively with minimal interferences therefore helping to optimize pharmaceutical packaging processes.